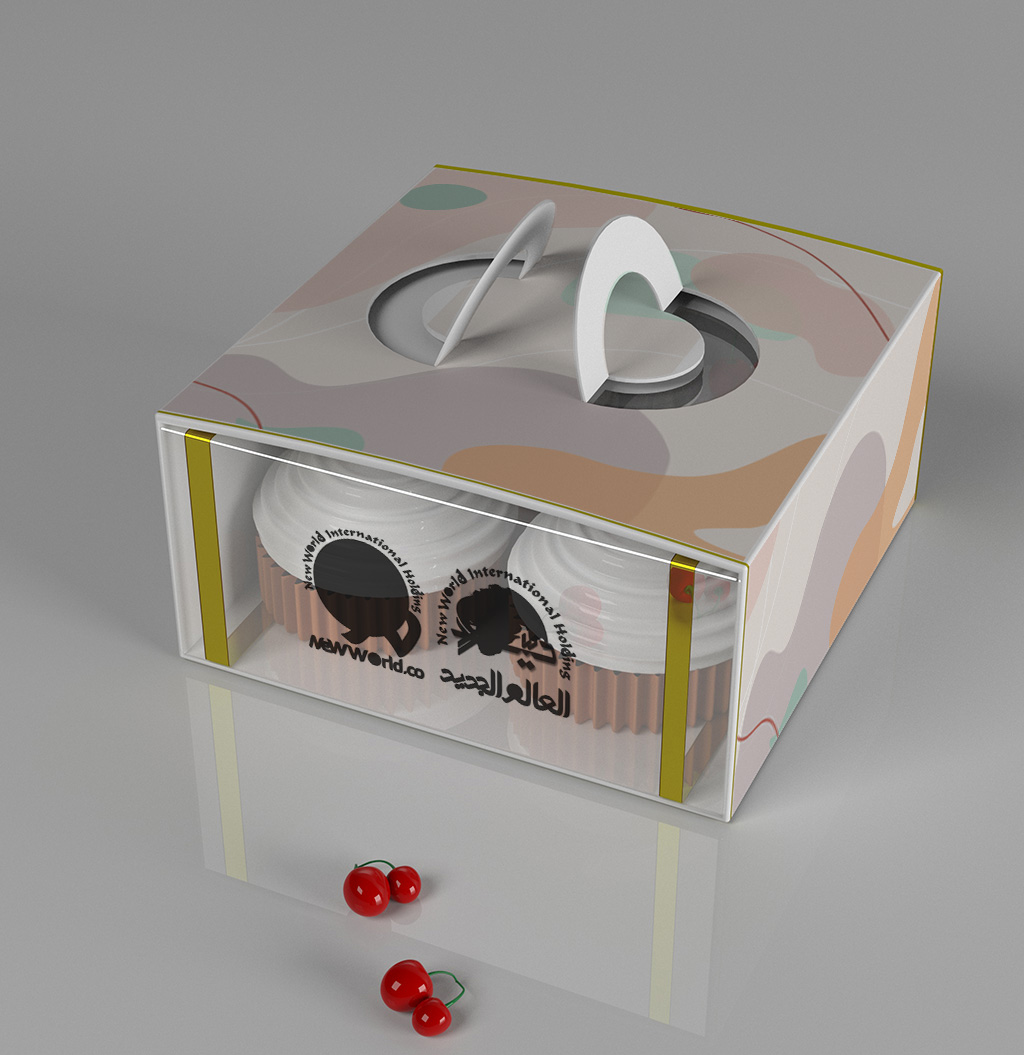

acrylic cake box

With more than 10 years of experience in the field of packaging industry, New world manufactures all kinds of talqi cake boxes, including: ready-made and customized talqi cake boxes with and without printing in different designs and dimensions.

Plastic Cake Boxes

Plastic cake boxes are considered one of the most popular types of packaging for cakes and pastries.

These boxes are designed to preserve freshness, ensure easy transportation, and provide an attractive display for cakes.

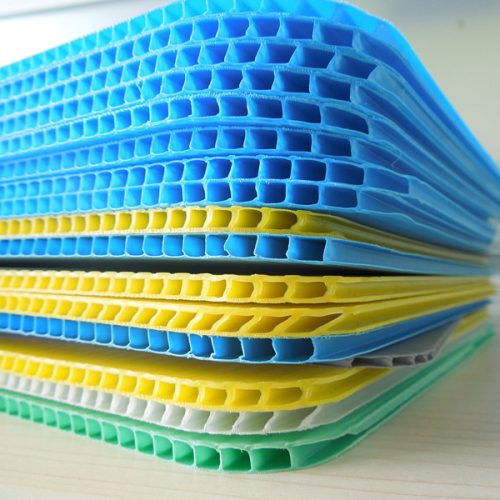

Various materials are used in the production of plastic cake boxes, but they are generally made from durable cardboard and high-quality plastic, which gives the box a strong and sturdy structure.

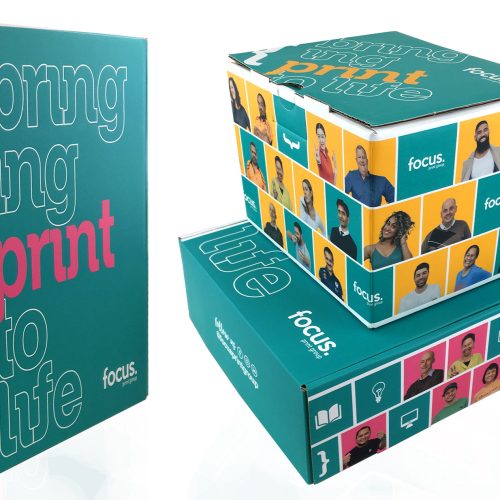

Plastic cake boxes are recognized as elegant and luxurious packaging.

They feature diverse and attractive designs, the option to print logos or special text, windows for showcasing the cake’s beauty, and handles for easy carrying.

These boxes allow cake and pastry manufacturers to package their products to high standards and present them to their customers.

To purchase plastic cake boxes or inquire about their prices, you can contact the new world printing and packaging company.

Reviews

There are no reviews yet.