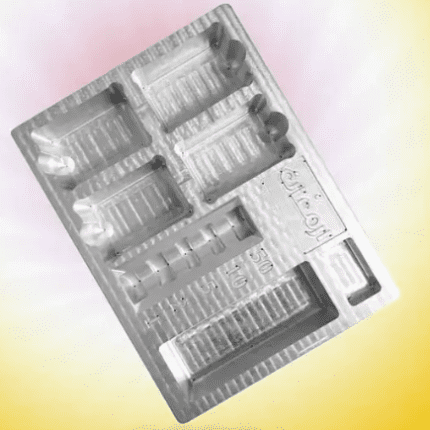

A vacuum forming mold is an important tool used to produce high-quality products. The mold must be made of materials that can withstand the heat and pressure of the vacuum forming process. It must also be made of materials that are compatible with the plastic that is used to produce the product.Molds are typically made of aluminum, steel, or wood. Aluminum is a popular material for molds because it is lightweight and affordable. It is also a good conductor of heat, which can quickly heat and cool. Steel is a more durable material than aluminum and can withstand more heat and pressure. Wood is a less expensive material than aluminum and steel, but it is not as durable.Molds must be properly designed to ensure that the finished product is of high quality. The mold design must be accurate to produce the product with the desired shape and size. It must also be smooth to ensure that the product surface is smooth and free of defects.Molds must be regularly maintained to ensure that they perform well. They must be cleaned of any damage or defects. They should also be lubricated to prevent the plastic from sticking to them.

- Home

- About New World and Licenses

- Services

- Consulting and Marketing – season 1

- Chapter2 – Designing, Photography, Filmmaking

- Chapter3 – Printing, Packaging, Post-print

- Chapter 4- Environmental Advertising and Exhibition Services

- Chapter 5 – Audiovisual Advertising and Electronic Marketing

- Chapter 6 – Advertising gifts

- Chapter 7- The world of distribution

- Chapter 8- Export and Import

- Log in

- Membership

- Contact us

English

Quick access

- Chapter1 - Consulting and Marketing

- Chapter2 - Designing, Photography, Filmmaking

- Chapter3 - Printing, Packaging, Post-print

- Chapter4 - Environmental Advertising and Exhibition Services

- Chapter5 - Audiovisual Advertising and Electronic Marketing

- Chapter6 - Advertising gifts

- Chapter 7- The world of distribution

- Chapter 8- Export and Import

Contact us

Iran branch

Unit 10, 3th Floor., No.176, Opposite Haghighat Talab Alley., Beginning Ostad Nejatollahi (Villa) St. , Karimkhan Zand St., Tehran, Iran

Office:

+98-21 888 09590

:Mobile

98-912-1390484+

Iraq branch

19 unit, Third Floor, Near Maxi Mall, Branch 2, Arasat Al-Hindiyah, Outer Karrada, Baghdad, Iraq

+964-7800224224

+964-7741111224

+964-7750000442

Please coordinate with the group's experts before the personal visit.