- Chapter1 -Consulting and Marketing

- Chapter2 – Designing, Photography, Filmmaking

- Chapter3 – Printing, Packaging, Post-print

- Chapter 4- Environmental Advertising and Exhibition Services

- Chapter 5 – Audiovisual Advertising and Electronic Marketing

- Chapter 6 – Advertising gifts

- Chapter 7- The world of distribution

- Chapter 8- Export and Import

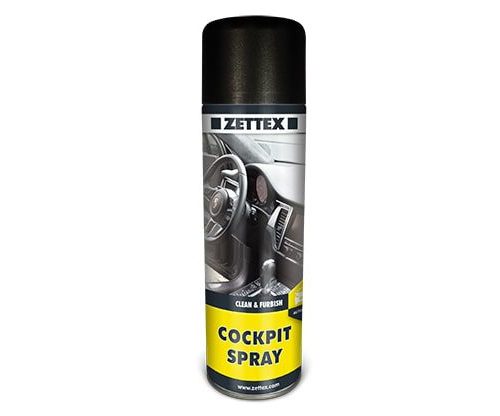

Adhesive Spray Can

New World is a leading manufacturer of Adhesive Spray Can and various metal (tinplate) and aluminum spray cans in various diameters, heights, and volumes. We provide top-quality services in can production, can printing, spray filling, shrink wrapping, and packaging.

Category: Tin Plate Spray Can

Description

The use of adhesive in the form of a spray can is considered one of the advantages of packaging this product. The shape of the adhesive spray can allows for a wide range of applications. The use of adhesive spray cans for hard-to-reach surfaces and objects, a wide range of spray coverage, high ease and speed of use, cleanliness, and high usability compared to aluminum tubes has led to the adhesive spray can being known as an all-purpose adhesive in the market.Adhesive spray cans are extensively used in artistic works such as crafting and gluing various flyers and announcements, as well as bonding wood and plastic. They have gained a large number of enthusiasts due to their high adhesive strength and quick drying time. Tinplate spray cans are usually used for this purpose.The packaging of adhesive materials in the form of spray cans is usually done as follows:

- First, the printing stage on the metal is carried out, including the product name, expiration date, contact information, manufacturer, and safety warnings.

- The can is shaped into a cylinder, and its valve is mounted on the body of the cylinder.

- Initially, any water leakage from the can is removed to ensure that the cans are leak-free.

- The valve is installed.

- The adhesive materials are charged into the spray cans. In this process, a certain amount of high-pressure gas may also be injected into the spray cans to prevent an increase in internal pressure during packaging.

- After charging the adhesive materials into the spray cans, the cans’ lids are installed, and a strong burst of gas may be injected to seal them.

- Finally, the spray cans are packaged in boxes and prepared for market distribution.

For further consultation and pricing inquiries regarding the production of tinplate spray cans, please contact us.

Be the first to review “Adhesive Spray Can” Cancel reply

Reviews

There are no reviews yet.