Flexo cardboard printing

New World has over 25 years of experience in providing packaging and printing services, including flexo carton printing, using the latest flexo carton manufacturing machines. Contact us for purchases.

In flexo printing on cartons, the sheet is precisely cut, creased along the path, and then the desired image or photo is printed on the carton sheet. This method allows printing up to 6 colors on the carton.

At the New World Design, Printing, and Advertising Company, all of the above operations are carried out with a fully automatic flexo machine.

There is a method for direct printing on cardboard sheets called flexographic printing (flexo), which can be applied to all sides of the cardboard or on one or two sides with single-color to four-color printing. For flexo printing, gelatin plates are made, which are then attached to the flexo printing machine to carry out the printing process.

Flexographic printing machines use raised plates (which can be created using analog or digital methods). The function of these plates is such that the areas to be printed are raised above the areas that are not printed. After placing the plate, images and text are molded using materials like rubber, and once the images and text are created, the plate is affixed to its appropriate position on the roller. Ink is then transferred to the plate and, ultimately, this ink along with the desired images and text is printed onto the target surface.

Flexographic printing with a rotary cylinder machine

Flexographic printing with a column machine

Flexographic printing with a flatbed machine, which is commonly used for printing on cartons

Flexographic printing has many advantages, including:

High-speed printing

Cost-effectiveness

High quality

Low cost

The stages of flexographic printing for cartons are:

Unwinding the roll

Printing

Drying

Rewinding the roll

The process of printing and producing cardboard cartons with flexographic printing includes the following steps:

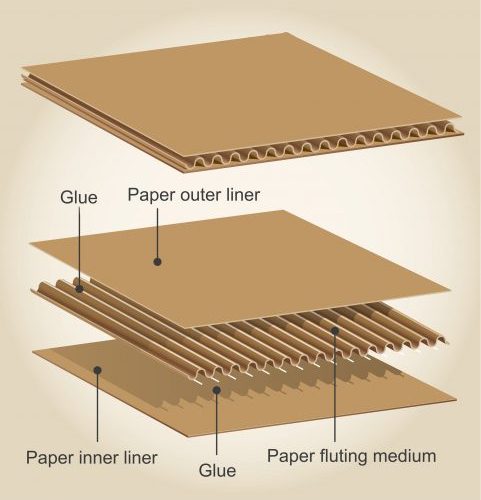

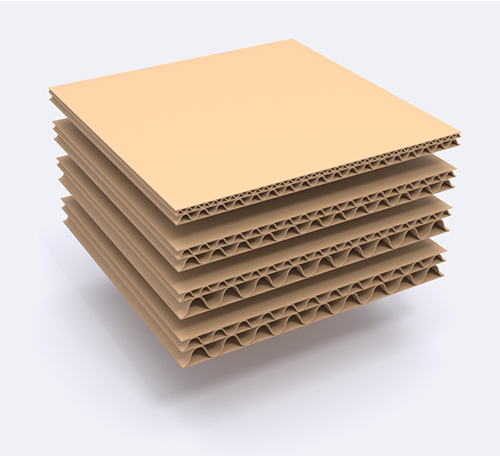

Preparing the sheets (three-layer, semi-layer, and seven-layer)

Cutting the sheets

Setting up the plate for printing

Printing the plate onto the cardboard sheet

Gluing and packaging

In flexographic printing for cartons, the sheet is first precisely cut and then scored. This cutting and scoring process is done using specialized machines.

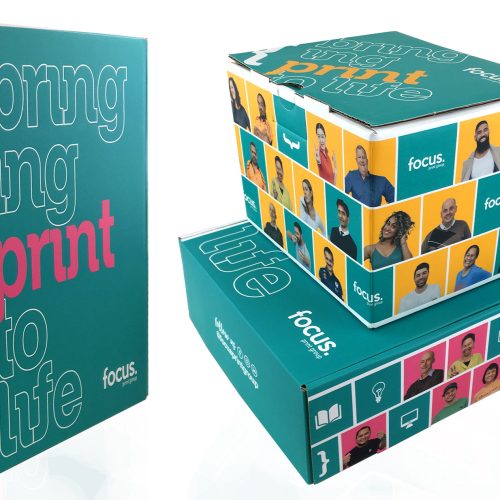

Then, using flexographic printing technology, the desired image or design is printed onto the cardboard sheet. This image can include graphic designs, text, logos, and any type of pattern or design.

One unique feature of flexographic printing on cartons is the ability to print up to six colors.

This allows for a greater color variety in carton designs and images, resulting in an attractive and appealing appearance.

Additionally, flexographic printing on cartons enhances the durability and longevity of the printed image and design, making the cartons more resistant to moisture, impacts, and other damaging factors.

Automatic flexographic printing machines are used in the design and printing company, New world.

These machines use advanced technologies and powerful software to carry out printing operations automatically and with high precision. This allows designers and advertisers to print their images and designs on cartons with high quality and accuracy, ensuring satisfaction with the final result.

Using flexographic printing on cartons enables you to effectively showcase your brands, enhance the appeal and strength of your products, and establish a connection between your customers and your brand, ultimately impacting sales and brand recognition.

Reviews

There are no reviews yet.