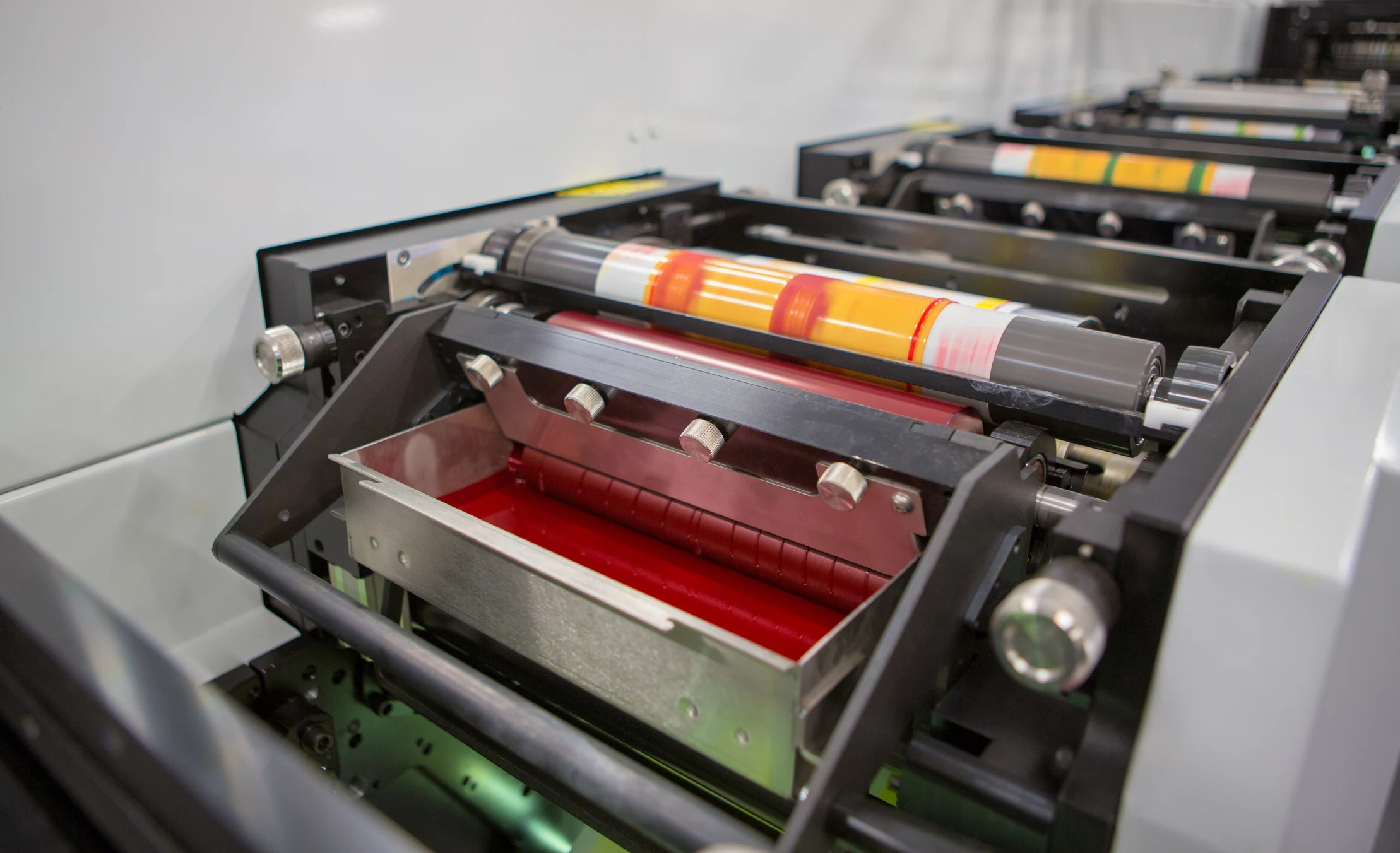

Flexo roll printing

Flexographic Roll Printing, also known as flexo printing, derives its name from the Latin word meaning “flexibility.” It is used for printing on flexible materials such as plastic, paper, cellophane, foil, nylon, and more.

Flexographic printing is a method that uses a gelatin-based plate. This plate is attached to a cylinder, and the printing process takes place. In a flexo printing machine, cutting and stitching processes occur simultaneously, which results in saving both time and cost.

For flexo printing, each color requires a separate plate, which can be made either analog or digital.

Various types of food packaging, dairy products, dried fruits, beverages, mineral water, legumes, canned goods, and cellulose products are printed using the flexo printing method.

Materials suitable for flexographic roll printing include:

- Foil

- Metallized film

- Polypropylene

- Cellophane

- Nylon

- Polyester

- PVDC

- Polyethylene

- Various types of paper

- Film wraps

- Shrink wraps

- Different types of paper and ribbon

Reviews

There are no reviews yet.