Laminated cardboard

With more than 25 years of experience in the field of packaging, , New world is a manufacturer of all kinds of cardboard boxes and cardboard boxes, including laminated cartons (laminated boxes), please contact us for orders.

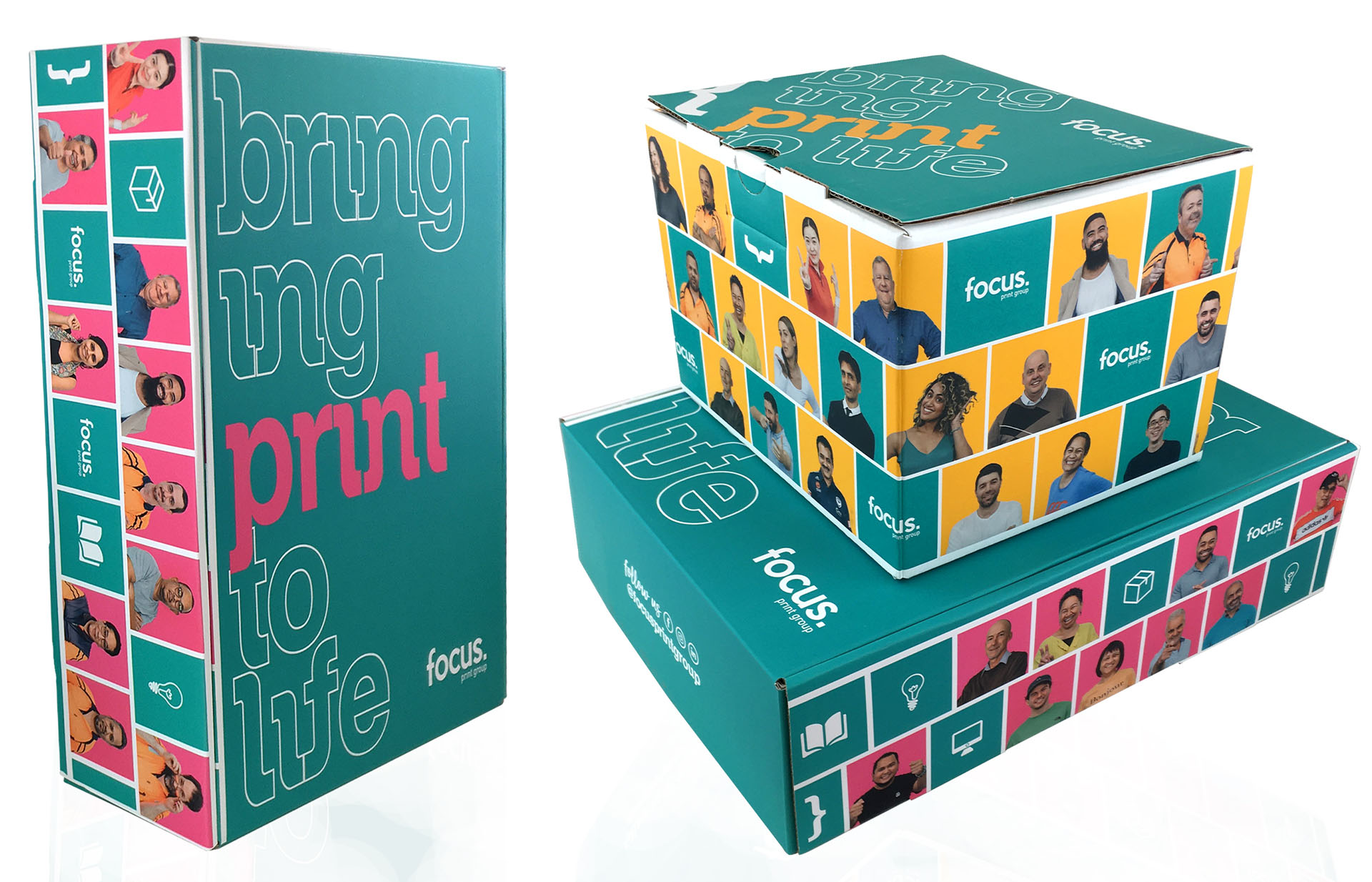

Laminated Carton: The Secret to Stylish and Durable Packaging

Laminated cartons are a new generation of cardboard boxes that combine a luxurious appearance with strength, making them ideal for packaging special and valuable products.

What is a Laminated Carton?

In essence, a laminated carton is a type of cardboard box covered with a thin layer of plastic or paper. This coating not only enhances the visual appeal but also adds strength and resistance against moisture, tearing, and scratches.

Advantages of Laminated Cartons:

Luxurious and Attractive Appearance: Laminated cartons feature high-quality printing and vibrant colors, offering a sleek and appealing look that helps attract customers.

High Durability: The laminate coating makes these cartons resistant to tearing, scratches, moisture, and impact.

Printability: High-quality printing of custom designs on laminated cartons is easily achievable.

Variety in Sizes and Designs: Laminated cartons can be produced in various sizes and designs, suitable for packaging a wide range of products.

Cost-Effective: Despite their numerous advantages, laminated cartons are more affordable compared to other packaging options like wooden or metal boxes.

Uses and Applications of Laminated Cartons:

Packaging of Luxury Products: Laminated cartons are perfect for packaging luxury items like perfumes, cosmetics, jewelry, watches, and more.

Food Packaging: These cartons are also suitable for packaging food items like sweets, cakes, chocolates, and more.

Gift Packaging: Due to their stylish and beautiful appearance, laminated cartons are ideal for gift packaging.

Purchasing Laminated Cartons:

To purchase laminated cartons, you can contact our experts for free consultation. We produce laminated cartons in various sizes and designs according to your needs.

Pricing of Laminated Cartons:

The price of laminated cartons depends on factors such as size, design, type of printing, and order quantity. For pricing information, please contact our sales experts.

Printing on Laminated Cartons:

Custom designs can be printed on laminated cartons using offset and digital printing machines. For printing on laminated cartons, you can contact our sales or design department.

Carton Lamination Process:

Carton lamination involves adhering a thin layer of plastic or paper to the carton surface. This process enhances the carton’s strength, aesthetics, and resistance to moisture and tearing.

Laminated Carton Manufacturing:

The production of laminated cartons includes several stages such as printing, lamination, cutting, and gluing.

Summary:

Laminated cartons are stylish and durable cardboard boxes used for packaging various products. They offer multiple benefits such as high printability, variety in sizes and designs, and cost-effectiveness.

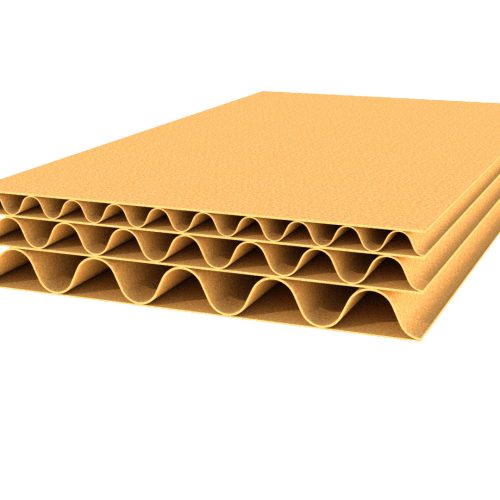

Laminated cartons can be 3-layer, 5-layer, 7-layer, or single-face. The process typically involves printing the desired design on the cardboard using offset printing, followed by laminating it on the carton sheets (3-layer, 5-layer, 7-layer, single-face), and then stapling or gluing.

Production Steps for Laminated Cartons:

Design the print.

Design the die-cutting line.

Create the template.

Prepare the printing plate.

Print the poster (usually on quality greyback cardboard or gloss paper).

Apply matte or glossy lamination.

Lamination process.

Die-cutting.

Gluing or stapling (for larger cartons, staples are used).

Uses of Laminated Cartons:

Laminated cartons are used for packaging fruits, electrical appliances, dates, and more.

At New world, all laminated cartons, from the smallest size to large dimensions, are produced with the best quality using the latest machinery for lamination, coating, and printing.

Laminated single-face boxes, 3-layer laminated boxes, 5-layer laminated boxes, and 7-layer laminated boxes are all produced with top quality at New world.

Laminated cartons feature a coating made from greyback paper (230 grams), glossy paper over 170 grams, or coated paper over 120 grams with a glossy or matte lamination (for greyback and glossy papers). This coating is applied over single and E flute, 3-layer to 7-layer cartons, in up to 6 colors (including silver and gold CMYK), a process known as lamination.

Reviews

There are no reviews yet.