mesh print

Mesh printing is a printing method that is prepared using mesh screens. These plates consist of thin, crossed wires that are assembled in a mold.

SKU:

E524F

Category: 5.18) Large format printing

Description

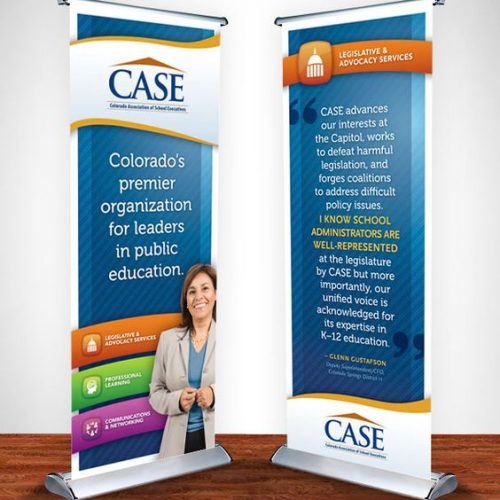

Mesh is a material with tiny holes, and the adhesive type can be applied to glass, allowing the glass to remain partially visible and not entirely obscured.

Below are some advantages, applications, and materials and equipment used in mesh printing:

Advantages:

- High Resolution: Using high-precision mesh screens, high-resolution images with fine details can be printed.

- Example: Printing photographic images, artistic images, and digital paintings.

- Versatility in Surfaces: With various types of mesh, printing can be done on different surfaces such as paper, fabric, leather, etc.

- Example: Printing on posters, banners, promotional fabrics, and other decorative surfaces.

- High Printing Speed: Mesh printing allows for the production of a large number of prints at high speed.

- Example: Printing large advertising materials, catalogs, and business cards.

Materials and Equipment Used:

- Mesh Screens: These screens are made of metal, such as steel or aluminum, and have high precision and clarity.

- Inks and Dyes: Various types of inks and dyes can be used for mesh printing, which print well on different materials.

- Mesh Printing Machines: These include linear or screen mesh printing machines capable of applying pressure and ink onto the mesh screens.

Disadvantages:

- Limited Color Range: In mesh printing, the number of usable colors is usually limited, and high color diversity cannot be achieved.

- Difficulty in Producing Complex Paintings: Due to the limitations of the mesh wires, producing complex paintings and images with high details can be challenging.

In conclusion, mesh printing is a powerful and widely used printing method in the printing industry. Despite its specific advantages and limitations, it offers diverse applications across various fields.

Be the first to review “mesh print” Cancel reply

Reviews

There are no reviews yet.