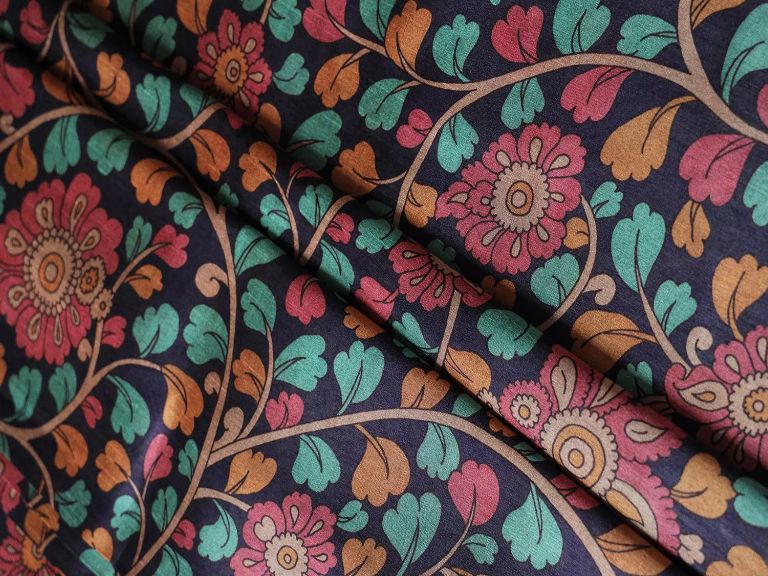

Offset printing on fabric

new world has more than 25 years of experience in providing printing services, including offset printing on fabric, which is done by the latest printing machine on fabric. Call to place an order.

Offset Printing on Fabric

Offset printing is one of the most popular methods for printing on fabric due to its high quality, variety of designs and colors, and cost-effectiveness, making it widely used in the textile and clothing industry.

What is Offset Printing on Fabric?

Offset printing is an indirect method for printing designs on fabric. In this method, the design is first transferred to a zinc or plate and then transferred to the fabric via rubber rollers. This process ensures high quality and image clarity due to the lack of direct contact between the zinc and the fabric.

Advantages of Offset Printing on Fabric:

- High Quality and Image Clarity: Offset printing reproduces design details precisely and with high clarity on fabric.

- Variety of Designs and Colors: Offset printing can print complex designs and a wide range of colors.

- Cost-Effectiveness: Offset printing is cost-effective for large quantities.

- High Speed: Offset printing is a fast process, allowing a large volume of fabric to be printed in a short time.

- Ability to Print on a Wide Range of Fabrics: Offset printing can be performed on various natural and synthetic fabrics.

Disadvantages of Offset Printing on Fabric:

- High Initial Cost: The cost of creating the zinc or plate in offset printing is high.

- Not Suitable for Small Quantities: Offset printing is not cost-effective for small quantities.

- Inability to Print Embossed Designs: Offset printing cannot print embossed designs on fabric.

- Requires Expertise: Offset printing requires the expertise and skill of the operator.

Steps of Offset Printing on Fabric:

- Designing: The desired design is created by a graphic designer using computer software.

- Making the Zinc or Plate: The design is transferred onto the zinc or plate.

- Preparing the Fabric: The fabric must be free of any dirt and grease before printing.

- Printing: The zinc or plate is placed on the rubber rollers, and the design is transferred to the fabric.

- Drying: After printing, the fabric must be completely dried.

What Types of Fabrics Are Suitable for Offset Printing?

Offset printing can be performed on various natural and synthetic fabrics. Some suitable fabrics for offset printing include:

- Cotton Fabrics: Such as cotton, linen, and flax

- Polyester Fabrics: Such as polyester and viscose

- Silk Fabrics: Such as natural and synthetic silk

- Wool Fabrics: Such as wool and cashmere

Applications of Offset Printing on Fabric:

Offset printing has extensive applications in the textile and clothing industry. Some applications of offset printing on fabric include:

- Printing on Clothing: Such as t-shirts, jackets, pants, scarves, and shawls

- Printing on Curtains: Such as home and office curtains

- Printing on Bedding: Such as bedspreads, sheets, and pillowcases

- Printing on Furniture: Such as upholstery and chairs

- Printing on Promotional Products: Such as bags, tote bags, and mugs

- Printing on Flags and Banners

Cost of Offset Printing on Fabric:

The cost of offset printing on fabric depends on various factors, such as the type of fabric, the desired design, the quantity, and the quality of the print.

This printing method uses multiple cylinders to apply ink to the fabric, with each cylinder applying a specific color. The design is applied to the fabric using a pre-determined plate.

This method is used for high-volume production.

Offset printing on fabric is generally performed in rolls.

In offset printing on fabric, the maximum width is 1.5 meters, and the use of standard inks enhances the quality and health of the fabric.

Various fabrics like velvet, polyester, semi-polyester, etc., are printed using this method.

Offset printing is not cost-effective for low volumes.

This type of printing uses two color systems:

- RGB Color System: Stands for red, green, blue, which are known as the primary colors. Combining these three colors creates various combined colors.

- CMYK Color System: Combines four colors—cyan, magenta, yellow, and black—to create different colors.

For fabric printing, the CMYK system should be used in design to ensure the print matches the design accurately with minimal color discrepancy.

Reviews

There are no reviews yet.