Post-printing services

Types of Coatings

The types of coatings in printing include matte and glossy UV, spot UV, adhesive and thermal matte and glossy lamination, acrylic UV, sandy UV, machine varnish, and lamination. These coatings are used to enhance durability, longevity, and the beauty and brightness of the colors. It is worth mentioning that Donyaye No Advertising Design and Printing has the capability to apply matte and glossy lamination with patterns, which is usually used for fancy printed works. All coatings have the ability to emboss patterns (MBUS). The cost of UV, lamination, and varnish differs, and each is added to the total printing cost.

- a) Lamination:

Sometimes, applying a coating on a printed product is essential. For example, if you want to print on 300-gram glossy paper and then fold it, the paper will likely crack, so lamination is necessary. In fact, lamination not only adds strength but also enhances the appearance of the product without increasing its thickness.

Simple laminations come in two types: matte and glossy, and the choice between them is a matter of preference.

Another type of lamination is velvet lamination, which is more expensive. Lamination can be applied in two ways, thermal or pocket, using a lamination machine, with thermal lamination being of higher quality and cost. The cost of lamination is calculated per square centimeter.

- b) Lamination:

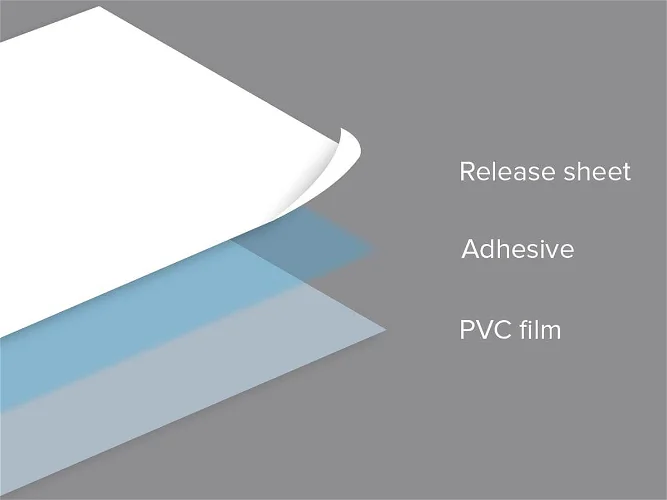

Another type of coating is lamination, which is essentially a thick plastic coating with a thickness ranging from 50 to 700 microns applied to the product. There are two types of lamination: matte and glossy. Laminating printed products can be done using either the thermal or cold method.

In thermal lamination, the printed paper is placed between the matte or glossy laminate, then inserted into a laminating machine. The machine uses a heater and press to warm the laminate, completing the lamination process. In the cold lamination method, the laminate itself has adhesive, and only pressing is required. This method is used for papers that are sensitive to heat.

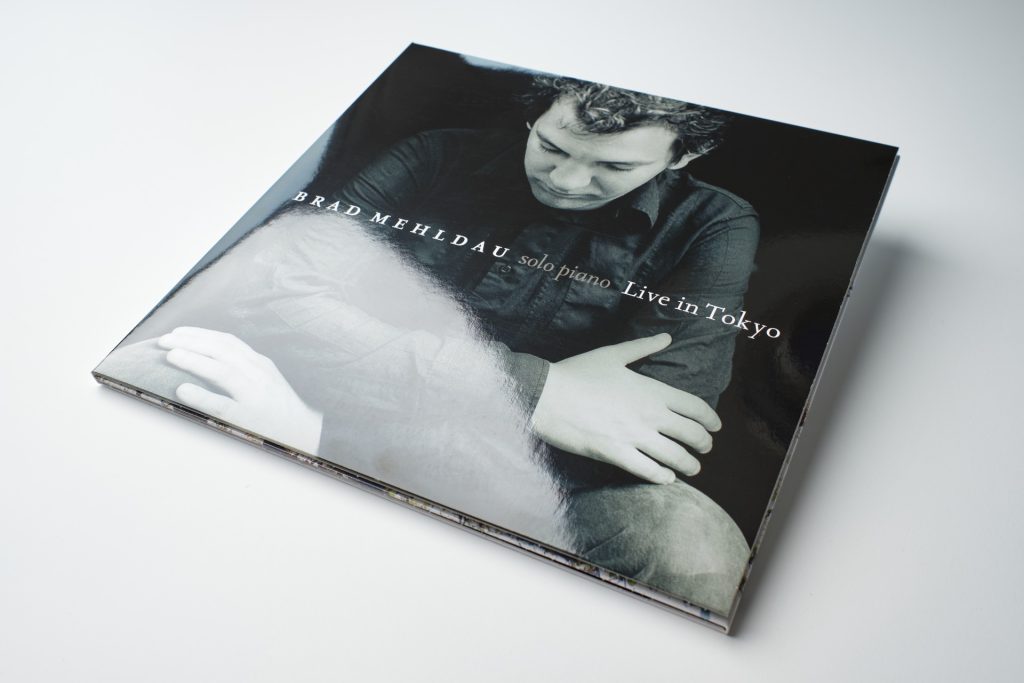

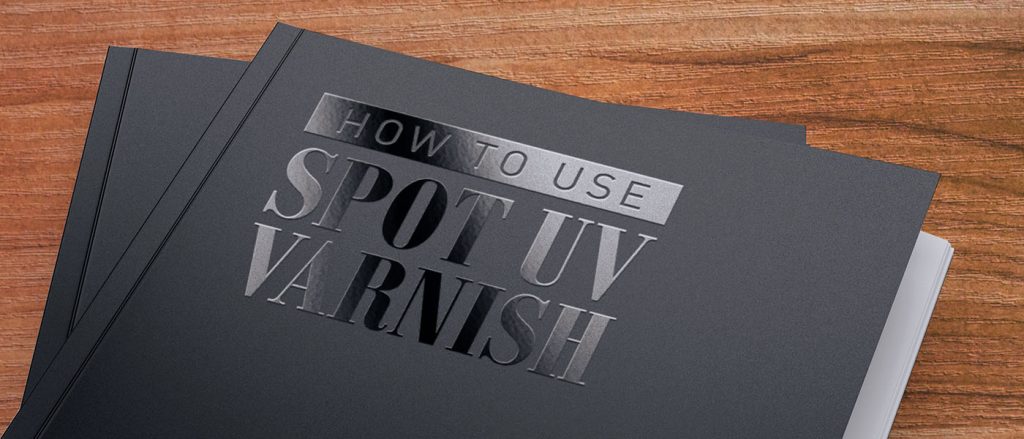

- c) UV Coating:

UV Coating adds gloss to the product but does not add to its thickness. UV coating is cured using ultraviolet light and is available in two types: cylinder UV and raised UV. Cylinder UV is used for more affordable projects. For raised UV, you need to make the areas where you want spot UV black in the file and then provide the file to the lithography department to create the spot UV film.

Spot UV can be applied in various ways, one of which is sandy UV.

- d) Varnish Coating:

Another type of coating is varnish, which can be applied in two ways: hot varnish and cold varnish. In the cold varnish method, varnish is mixed with ink in a specific ratio and transferred onto the paper during printing, helping to stabilize the color. This method is only used in offset printing. The hot varnish coating method uses a lithographic film to transfer the varnish to the desired area, and it does not make the product glossy.

The difference between varnish coating and UV coating is that varnish is primarily used to stabilize color in printing and is not easily noticeable in the appearance, while UV coating significantly enhances the glossiness of the product.

Step 1:

Model making and sampling require a design map, which is a detailed layout of the cutting and creasing patterns, including where the cuts and folds or glue lines will be.

Step 2:

The mold cuts are performed using laser and fully automated machines.

Step 3:

The blades are installed in their positions. In advanced methods, before production, all stages and the final result can be viewed virtually using 3D software.

Flat Molds:

Rotary Mold Production Process: Rotary molds are flexible molds that perform die-cutting simultaneously with printing. These molds are suitable for flexographic printing and offer very high quality.

Mold Punching (Letterpress, Die-Cutting, Bobs, and Embossing):

Mold punching for various boxes and embossing surfaces, as well as for arch molds and half-cut labels, is done using letterpress and die-cutting machines. At Donyaye No Design, Printing, and Advertising, all letterpress, die-cutting, bobbing, and embossing services are provided with the highest quality and the lowest prices using the most advanced machines and specialized personnel.

- a) Letterpress

This machine is used for mold punching and embossing.

It is worth mentioning that in the past, letterpress was used as a printing machine, where letters were embossed using the device. However, after offset printing machines became prevalent, letterpress machines are now used for post-printing services such as creasing, cutting, mold punching, and embossing.

- b) Die-Cutting

|

|

Die-Cutting:

The die-cutting machine, which combines hand and machine die-cutting operations, is used for small quantities and laminated molds. There are various types of die-cutting machines, which are more commonly used in the corrugated board industry. Examples of die-cutting machines include: platen die-cutters, flatbed die-cutters, rotary die-cutters, and flat die-cutters.

Bobst:

The Bobst machine is similar to letterpress but is more cost-effective for high volumes and large sizes. All operations that can be performed with a letterpress can also be done with a Bobst machine.

Different Box Gluing Models:

Simple Gluing Box:

The simplest type, where the box has no special coating, is folded along one side and glued.

Lock Bottom Box Gluing:

The bottom of the box opens and closes automatically. In a lock bottom box gluing machine, the cardboard box, after printing, is glued together in a fully mechanized manner. Precision, speed, and quality are crucial in a box gluing machine. The boxes produced using this method are designed so that when the box is opened, the bottom automatically opens and closes. These boxes, in addition to having very high durability, require very little storage space due to their special design.

Multi-Point Gluing Box:

Boxes that need to be glued at several points, such as fancy chocolate and biscuit boxes. Multi-point gluing generally involves gluing at 4 or 6 points. For example, in the 6-point gluing method, the box is glued at 6 points, and boxes glued at 6 points have a very attractive appearance. Examples include fancy boxes, chocolate boxes, and biscuit boxes.

Hot Melt Glue Box Gluing:

This method is used for boxes with a lamination or UV coating. Some boxes, such as those for shrimp, fish, or ready meals, are placed in environments like cold storage or freezers. For these, hot melt adhesives are used, which melt when heated and solidify as they cool.

Box gluing for non-laminated boxes, CD/DVD boxes, laminated boxes, labels, lock bottom boxes, point gluing, and desktop stands is performed in both single-piece and two-piece formats.

Box gluing can be done manually or with machines.

At New world Design, Printing, and Advertising, we offer the option of window gluing (window pack) as well.

Products categories

- Services

- Chapter1 -Consulting and Marketing

- Chapter2 - Designing, Photography, Filmmaking

- Chapter3 - Printing, Packaging, Post-print

- Part 5: Printing projects and related industries

- 5.1) Lithography

- 5.2) Offset printing

- 5.3) Digital printing

- 5.4) Printing PVC sheets

- 5.5)3D printing

- 5.6) Metallization printing

- 5.7) Talaq Printing

- 5.8) Print on fabric

- 5.9) Printing and burning CD

- 5.10) CNC and laser printing (engraving)

- 5.11) Gold blocking-hot stamping-embossed stamping

- 5.12) Tampo printing

- 5.13) Silk printing

- 5.14) Printing on metal

- 5.15) Printing on stone

- 5.16) Thermal printing

- 5.17) Roll printing

- 5.18) Large format printing

- 5.19) Seal and gelatin

- 5.20) Types of coatings

- 5.21) Molding

- 5.22) Stamping

- 5.23) Sticky box

- 5.24) Assembly

- 5.25) Post-press services

- 6. Technical office services

- 7. Binding

- part 8 - Holograms and Types of Labels

- 9. Packaging industries

- 9.1 Box

- 9.2 Board cover

- 9.3 Plexi boxes & Vaccum Forming

- 9.4 Fantasy boxes

- 9.5 Laminate and inner cover

- 9.6 Carton

- 9.7 Shrink

- 9.8 Air bubble nylon

- 9.9 Disposable food containers

- 9.10 Plastic containers

- 9.11 General format

- 9.12 Board can

- 9.13 Jar glass containers

- 9.14 Manufacturing sacks and industrial packets

- 9.15 Manufacturing and selling machineries

- 9.16 Food container

- part 10 - Shopping bag

- Part 5: Printing projects and related industries

- chapter4:Environmental Advertising and Exhibition Services

- Chapter 5 - Audiovisual Advertising and Electronic Marketing

- Chapter 6 - Advertising gifts

- part 24- Advertising gifts

- 24.1 Stationery

- 24-2 Stationary set

- Main brand stationary set

- Stationary set of CROSS brand

- Stationary set of SHEAFFER brand

- CANDID

- GHANARY desktop set

- Stationary set of WATERMAN

- Stationary set of PARKER

- Stationary set of HANSA

- Stationary set of PORTOK

- Stationary set of MELODY

- Stationary set of EUROPEN

- Stationary set of DIPLOMAT brand

- Stationary set of PIERRE CARDIN brand

- Miscellaneous brands' set (pen – fountain pen)

- Main brand stationary set

- 24.3 Card case

- 24.4 Keychain

- 24.5 Lighter

- 24.6 Ashtray

- 24.7 Main clothes (advertising cloth)

- 24.8 Subsidiary clothes

- 24.9 Advertising hat

- 24.10 advertising towel

- 24.11 Advertising cover

- 24.12 Advertising radio

- 24.13 Advertising clock and wristwatch

- 24.14 Advertising mug mat

- 24.15 Advertising mouse pad

- 24.16 Advertising car sunshade

- 24.17 Leather artifacts

- 24.18 Advertising document cover

- 24.19 Advertising folder and writing pad

- 24.20 Advertising index file and Zoonckan

- 24.21 Advertising bag and wallet

- 24.22 Advertising balloon

- 24.23 Advertising ruler

- 24.24 Advertising puzzle

- 24.25 Children's advertising gifts

- 24.26 Postcard

- 24.27 Advertising magnet (magnetic stickers)

- 24.28 Plexi file and bag

- 24.29 Advertising tissue and tissue box

- 24.30 Sculpture-pottery-tile

- 24.31 Advertising containers

- 24.32 Calculator

- 24.33 Office papers-fantasy paper-notepad

- 24.34 Lighting advertising gifts

- 24.35software gift

- 24.36 Advertising photo frame

- 24.37 Advertising photo album

- 24.38 Handicrafts

- 24.39 Special religious gifts

- 24.40 Doll making

- 24.41 Advertising tools

- 24.42 Women's special gifts

- 24-43) mobile accessory

- 24.44 Electronic gifts

- 24.45 Advertising hand fan

- 24.46 Special medical gifts

- 24.47 Advertising opener

- 24.48 Advertising (woven) carpet tableau

- 24.49 Advertising desktop set

- 24.50 Advertising air freshener

- 24.51 Umbrella

- 24.52 Advertising meter

- 24.53 Advertising tape dispenser

- 24.54 Optical advertising gifts

- 24.55 Advertising compass

- 24.56 Advertising thermometer

- 24.57 Automobile advertising gifts

- 24.58 Special gifts

- 24-59) Wooden promotional gifts

- part 25 - 26 - Almanac and telephone directory

- 27. Calendar

- part28- 27.1 Exquisite books

- part 24- Advertising gifts

- Chapter 7- The world of distribution

- Chapter 8- Export and Import

Online price inquiry

"*" indicates required fields

Quick access

- Chapter1 - Consulting and Marketing

- Chapter2 - Designing, Photography, Filmmaking

- Chapter3 - Printing, Packaging, Post-print

- Chapter4 - Environmental Advertising and Exhibition Services

- Chapter5 - Audiovisual Advertising and Electronic Marketing

- Chapter6 - Advertising gifts

- Chapter 7- The world of distribution

- Chapter 8- Export and Import