Printing on metal

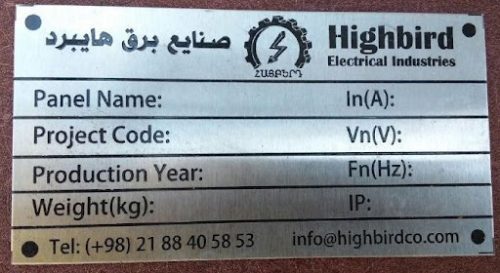

a) Manufacturing and Various Types of Printing: Labels, Plates, and Metal Logos (simple and embossed) in various colors and sizes with custom cutting and protective coating. The printing type includes baked enamel and UV coating.

In this collection, steel, aluminum, and brass plates and labels are produced.

|

|

|

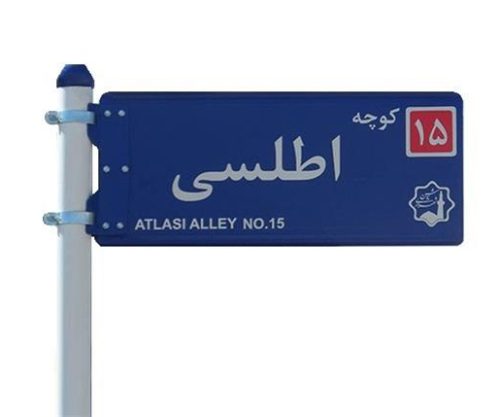

b) Production of postal code plates, water and gas subscription plaques, and recessed and raised metal properties.

|

|

“c) Printing and lacquering on sheet iron, tin, etc., in a flat form, such as metal signs

|

|

|

|

d) Printing of various metal labels and specification plates (riveted and bubble-backed)

|

|

|

|

e) Stamping serial numbers on firearms (manufactured products)

|

|

|

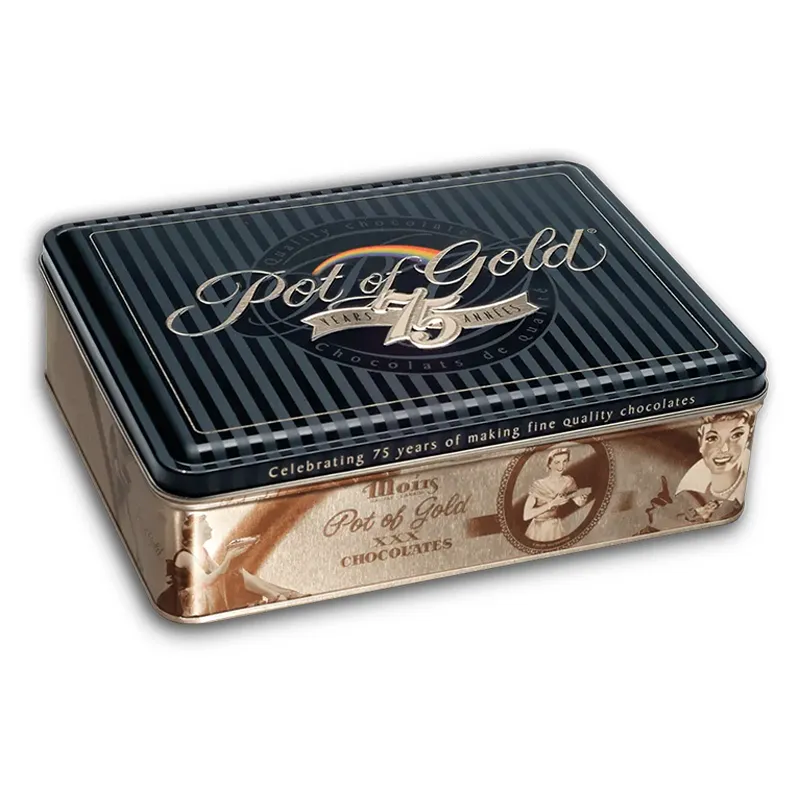

f) Printing on various round and square metal cans in different sizes

|

|

|

g) Printing on various pharmaceutical and sanitary metal tubes

|

|

|

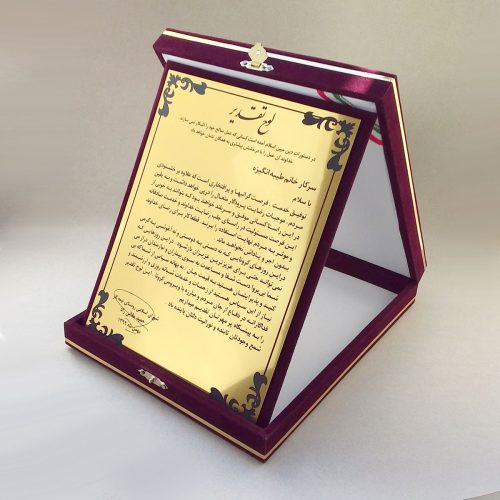

“j) Manufacturing and printing of various medals, trophies, and metal plaques of appreciation

|

|

|

|

In the case of the above-mentioned prints that require durability and high quality, especially for outdoor applications or surfaces exposed to sunlight, printing is done with UV ink.

The price of metal printing depends on specifications such as quantity, size, color, type of coating, type of metal, etc.

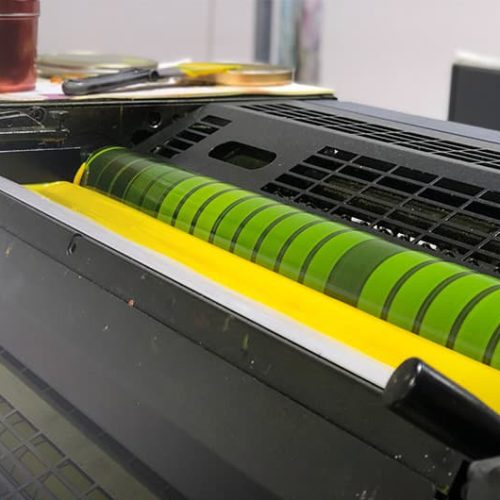

Printing on metal can be done in two ways: 1. Digital printing on flatbed metal 2. Offset printing on metal

Flatbed or Digital: The best machine for digital printing on flat metal is the UV flatbed printer, which applies ink directly onto the metal surface; once the design is printed on the metal sheet, it is dried using UV light. Before printing, the sheets must be degreased and spark-treated. The ink used for metal printing must have good durability; otherwise, it won’t withstand various weather conditions. There are no size limitations in metal printing, and various images can be printed on different types of metal sheets. The metal sheets that are printed with the digital machine must be immediately placed in the oven.

Depending on the type of product placed in the metal cans, various coatings are used for the inside of the cans.

Digital printing on metal is typically used for metal plaques, signs, logos, etc.

Direct printing on metal is mostly done using digital flatbed printers. This type of printing can be done on various metals such as galvanized steel, aluminum, copper, etc.

The output of this printing (digital flatbed) is of very high quality and is used for advertising boards and plaques.

The cost of direct digital flatbed printing on ordinary metal is calculated based on square meters.

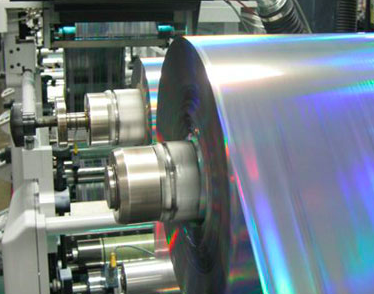

Offset printing on metal is performed using lithographic plates and is a primary method for printing on metal cans.

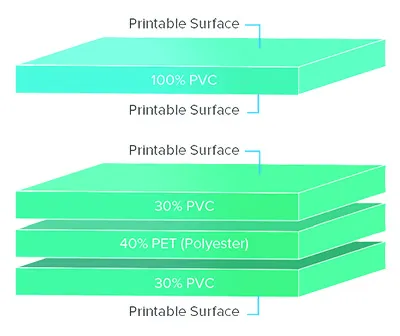

For printing on metal, the metal sheets must be covered with a coating before printing and then sent for printing. The metal sheets have a thickness of approximately 0.18 to 0.3 mm, depending on the type of work, and are usually first coated with white paint or white lacquer so that the printed colors are displayed well.

After printing, a varnish operation is performed on the metal, then the sheets enter a drying oven, and finally, the metal sheets are stacked for cutting and converted into cans at the can manufacturing workshop.

For direct printing on metal (digital flatbed), the file must be in CMYK format with a resolution of at least 150 DPI.

In digital printing on metal (UV flatbed), the ink is applied directly onto the metal, and the printing is carried out, using high-quality inks to maintain color stability. The ink is then dried by UV exposure.

This type of printing is used for directional signs in various locations.”

|

|

|

|

|

|

|

The maximum print size in flatbed digital printing is 250×160 cm. Flatbed printing does not require an oven and dries with UV exposure. Metal sheets up to a thickness of 9 cm with a flat surface can be printed using the flatbed method.

UV flatbed printing is resistant to sunlight and rain, and flatbed digital printing offers very high resolution quality up to 1200 dpi.

In direct metal printing (flatbed digital printing), metal sheets must first be degreased and then subjected to spark treatment before printing is done.

|

|

|

|

2- Offset Printing on Metal:

Offset printing on metal is done using lithographic plates and is a primary method for printing on metal cans.

Before printing, metal sheets must be coated with a protective layer and then sent for printing. The thickness of metal sheets ranges from about 0.18 to 0.3 mm, depending on the type of work. Typically, they are first coated with white paint or white lacquer to ensure the printed colors stand out well.

After printing, a varnish process is applied to the metal, then the sheets are sent to a drying oven. Finally, the metal sheets are stacked and sent to the can manufacturing workshop for cutting and shaping into cans.

This type of printing includes several stages:

- a) Selecting the material

- b) Printing size

- c) Primer color

- d) Design printing

- ) Protective lacquer on the metal.

|

|

This type of printing is used for industries such as can manufacturing, metal boxes, and spray cans. First, the film and plate (zinc) of the desired design are prepared, and printing is done through an offset printing machine using the film and plate on degreased and treated surfaces.

Offset printing on metal can be done in large volumes.

After the final color is printed, varnish is applied to the work, and the sheet is placed in an oven to fix the color and print (a detailed explanation regarding metal boxes and spray cans will be provided in the following sections). Another type of direct printing on metal is silk screen printing or pad printing, but these methods have limitations in terms of color, design, and size.

|

|

The New World group specializes in printing and manufacturing various types of labels, plaques, and metal logos, both simple and embossed, in different colors and sizes, with custom cuts and protective coatings, all done with the best quality. The type of paint used is baked and cured.

They manufacture postal code plaques, water and gas subscription plaques, as well as embossed and recessed metal property tags, yellow printing and varnishing on tin sheets, metal labels with barcodes, serial numbers on metal, and printing various round and rectangular metal cans in different sizes. They also produce various aluminum tubes.

For the aforementioned printing projects, especially those that require durability and high quality in outdoor environments or surfaces exposed to sunlight, UV ink printing is employed. The price of metal printing depends on specifications such as quantity, size, color, type of coating, type of metal, and so on.

Reviews

There are no reviews yet.