Silk print

New world holding With more than 25 years of experience in providing silk screen printing services, silk printing on fabric, manual silk, PCB with the latest silk printing machine, contact us to place an order.

Silk Screen Printing:

Silk screen printing is used on flat surfaces such as paper, cardboard, labels, reflective sheets, plastic, and fabric, using separated colors. It is commonly employed for printing on paper, nylon shopping bags, transparent labels, and more. In silk screen printing, a stencil or cliché is used. This method is also applied for promotional printing on various objects or promotional gifts, such as calendars and planners.

Disadvantages of Silk Screen Printing Compared to Offset Printing:

The downsides of silk screen printing include lower speed, limited capacity, lower resolution, and restrictions in color blending during the printing process.

Silk screen printing is one of the methods used in the printing industry, where ink is transferred onto the printing surface using a mesh of fine polyester threads. In this technique, the silk mesh is placed over the printing template, and with the help of a special tool known as a printing brush, the ink is precisely applied to the surface. Despite being one of the oldest printing methods, silk screen printing is still widely used in industries such as advertising, clothing, stationery, and other printed products.

Silk Screen Printing: Creativity in the Packaging and Printing Industry

In today’s dynamic world, silk screen printing has established itself as a prominent technique in the packaging and printing industry, standing out with its excellence in advertising and brand promotion.

Artistic Effects and Impact

Although new technologies have emerged in the field of modern printing, silk screen printing has maintained its place, continuing as a beautiful and valuable art form. The effort to combine this art with technological innovations ensures its future and contributes to its development.

One of its appealing features is the ability to create unique artistic effects and special impacts. These effects include glossiness, multi-layered designs, and incredibly vibrant colors.

|

|

Exceptional Services of New World in the Field of Printing

Why New World? Exceptional Services

Looking at the special services of New World in silk screen printing, it becomes clear why this company is chosen over its competitors. From advanced technologies to a specialized artistic team, New World ensures the longevity of your brand.

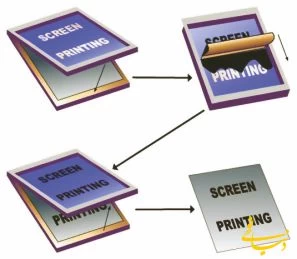

Silk screen printing is a process where ink or paint is applied to the desired surface using a silk screen template. This silk template consists of a mesh of fine threads used to create the desired pattern on the target surface.

In this process, the silk screen is placed on the surface, and ink or paint is transferred through the mesh onto the surface. This method is used for printing on various materials such as fabric, paper, plastic, and more.

Due to its high precision and ability to print on various surfaces, it is widely used in industries such as advertising, clothing, stationery production, and more.

The Steps of Silk Screen Printing:

- Preparation of the Mesh , which is placed in special templates, commonly referred to as stencils.

The finer the mesh, the higher the printing cost. The templates are generally made of wood or metal.

- In the next step, pre-determined ratios of sensitizing materials and lacquers are mixed. After preparation, tables equipped with simple or UV lights are used, and the printing is done manually or automatically.

One type of silk screen printing, cylindrical silk screen , allows printing on circular objects like mugs, buckets, or round food containers, done with automatic or manual cylindrical silk screen machines.

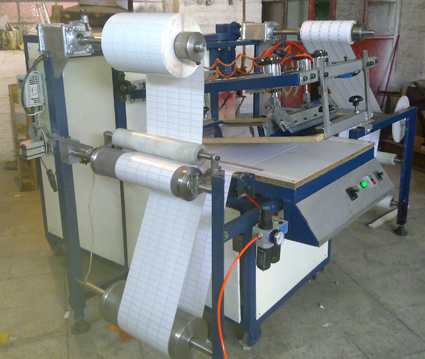

Roll-to-roll printing is also used for printing on paper or fabric.

Additionally, silk screen printing is performed on flat surfaces such as paper, cardboard, labels, reflective sheets, plastic, and fabric, using separated colors. It is typically used for printing on paper, nylon shopping bags, transparent labels, and more.

In this type of printing, a stencil or cliché is used. Silk screen printing is also used for promotional printing on various objects or promotional gifts like calendars and planners.

Disadvantages compared to offset printing include slower speed, limited capacity, lower resolution, and restrictions in color blending.

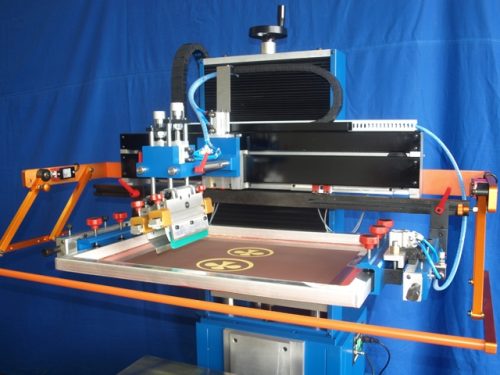

Here are some of the most famous silk screen printing machines.

|

|

Examples of types of silk printing

Silk printing on cardboard and envelopes

|

|

|

|

Silk printing on nylon and plastic

|

|

|

Silk printing on fabric (handbags and t-shirts)

|

|

|

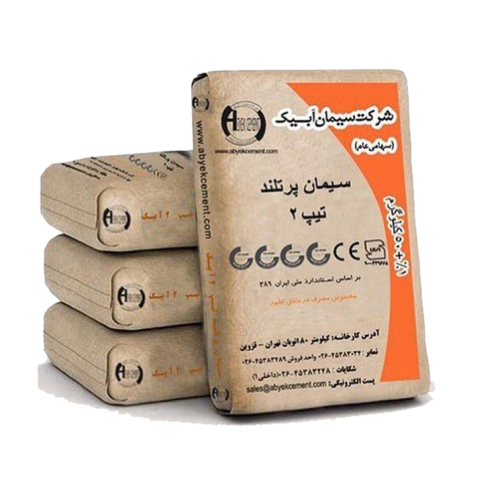

Silk printing on sacks (cloth and plastic), hats, flags and game boards:

|

|

|

|

Reviews

There are no reviews yet.