Tampo print

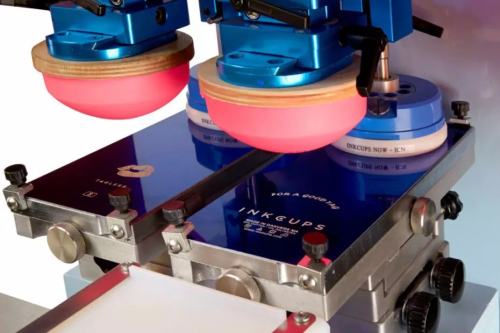

Tampo printing is a method of digital printing in which the ink is transferred by means of a tampo on the desired surface.

Pad Printing (Tampo Printing):

Pad printing is a technique used for printing on surfaces such as plastic pens, PVC mugs, or any plastic parts using separated colors. This printing method has limitations in size and is suitable for smaller dimensions. One of the main advantages of pad printing is its ability to print on various materials and surfaces with different shapes. With pad printing, it is possible to print on flat, cylindrical, curved, and spherical surfaces. The transfer of ink in pad printing is done using a silicone rubber pad, which is called a “tampon” or “pad.” Due to the pressure applied by the pad on the item, a fixture needs to be made for the item being printed.

For pad printing prices, please contact the design, printing, packaging, and advertising company “New World.”

Pad printing is a process in which a printing plate, usually made of metal or silicone, is placed on the surface of the desired object. Ink is then transferred to the printing plate using a pad, and finally, it is printed on the surface of the object. Pad printing is considered a high-quality multi-color printing method for flat and irregular surfaces, including stationery, household items, sports equipment, and other products.

|

|

|

Pad Printing:

Pad printing is a printing method in which ink is transferred to the surface of a product using a pad (or printer). This method is used to print on both flat and non-flat surfaces such as plastic, metal, glass, wood, and more. In this process, the pad picks up ink from the printing plate and transfers it onto the product’s surface. Pad printing is commonly used for printing logos, brand names, serial numbers, etc. Due to its high speed, precision, and ability to print on various surfaces, it is widely utilized in industries such as automotive, electronics, medical devices, and more.

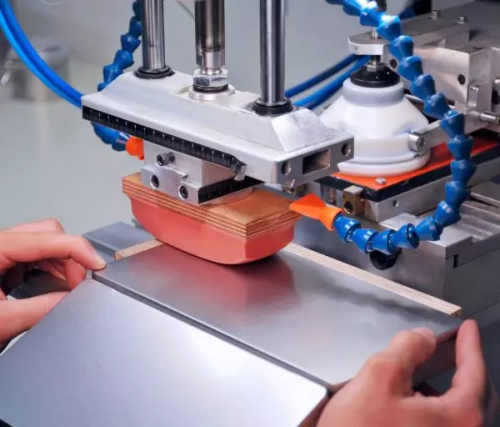

The pad printing process can be divided into three stages:

- Design and creation of the cliché (printing plate)

- Mold and fixture fabrication

- 3. Printing proces

|

|

The pad printing machine comes with either a closed system (cup system) or an open system (blade system). In the closed system, the ink is poured into a container, which helps save ink and is suitable for high-volume work. However, in the open system, a blade is used instead of a container, and the ink is exposed to the open air, which may cause the ink to dry faster.

In pad printing, industrial inks are used. When selecting the ink, the material of the product should be considered, and the ink must be compatible with the material to ensure that it adheres well to the product.

|

|

|

|

Reviews

There are no reviews yet.