Fabric Printing

Fabric printing is a process in which patterns, designs, and images are printed on fabrics. This process is one of the oldest methods of decorating and designing fabrics, and various techniques and tools have been developed for this purpose over the years. Today, fabric printing is a popular method in the fashion and decoration industries. This process allows designers and artists to showcase their creative and unique designs on fabrics, and thus provide products with higher quality and appeal to customers.

Types of Fabric Printing

1) Direct Digital Fabric Printing2) Offset Printing on Fabric3) Heat Transfer Printing on Fabric4) Silk Printing on Fabric5) Fabric Label Printing (Cutting)6) Flock Printing7) Embroidery

1) Direct Digital Fabric Printing

In direct digital fabric printing, color is applied directly to the fabric surface using specialized printers, which are expensive but offer high-quality and precision. In this method, ink is poured onto the fabric surface through a printer’s printhead and penetrates the fabric fibers. There are no limitations in color or design in direct fabric printing, and the image is transferred to the fabric with the best quality.Direct printing or DPG is costly due to the high price of the printers and provides excellent results on nylon, polyester, acrylic, artificial fibers, satin, linen, and velvet fabrics.Direct fabric printing can be done in both roll and sheet forms. The advantages include no limitations in colors. However, due to high costs and slow speed, direct digital printing (DPG) is less commonly used for large quantities.Direct printing is carried out using UV printers, ensuring high durability and preserving the fabric’s original texture. It offers high-quality and long-lasting results, with a maximum print width of 3.20 meters.

2) Offset Printing on Fabric

Offset fabric printing involves spreading ink on the fabric using multiple cylinders, each cylinder applying a specific color to the fabric. The design is applied to the fabric through a pre-defined plate.This method is suitable for high-volume printing and is generally done in roll form. The maximum width for offset fabric printing is 1.5 meters. Standard compounds enhance fabric quality and integrity, and this method is used for velvet, polyester, semi-polyester, and other fabrics.Offset printing uses two color systems:

- a) RGB Color System: Red, green, and blue are combined to create various mixed colors.

- b) CMYK Color System: The combination of cyan, magenta, yellow, and black produces different colors.

CMYK color system should be used in fabric design to ensure precise color matching and prevent significant color discrepancies.a) T-shirt Printing

b) Rhombus Fabric and Other Decorative Coatings

b) Rhombus Fabric and Other Decorative Coatings c) Fabric Toys with Prints (e.g., Dolls, Game Boards)

c) Fabric Toys with Prints (e.g., Dolls, Game Boards) d) Fabric Bags

d) Fabric Bags

e) Rice Bags

e) Rice Bags

f) Fabric Advertisements

f) Fabric Advertisements g) Flag Printing

g) Flag Printing

3) Heat Transfer Printing on Fabric

Heat transfer printing (sublimation) can be done in roll or piece form. It is suitable for light-colored polyester fabrics and does not work on natural fibers like cotton and linen.The fabric must withstand a temperature of 200 degrees Celsius. For roll printing, roll-to-roll plotters and calender machines are used, while cut pieces are printed using flatbed or industrial sublimation plotters and manual or calender press machines.In heat transfer printing, the design is first printed on transparent papers and then transferred to the fabric through heat. Sublimation ink turns into gas through heat and solidifies when transferred to the fabric.Sublimation or heat transfer printing is suitable for surfaces like T-shirts, mugs, puzzles, etc. Using high-quality paper enhances print quality significantly.

4) Silk Printing on Fabric

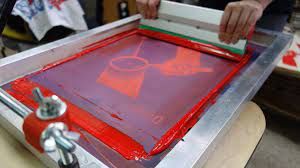

In silk printing, separate screens are used for each color. For example, if the design has four colors, four separate screens are used, and each screen transfers one color to the fabric.Silk screen printing is a method where a designed image is printed on a flat surface using silk screens, ink, and specific squeegees.The steps for silk screen printing are as follows:1) The desired design is printed on calico paper in black and white.2) Depending on the desired surface and fabric type, a suitable screen is chosen. This screen is coated with a light-sensitive substance and dried in a light-free environment. When exposed to light, it hardens, creating a stencil.3) A special sheet containing the design is attached to the stencil. The entire setup is exposed to strong light, making the exposed parts of the stencil hard and firm, while the remaining screen areas covered by the design remain soft.For each color, a separate stencil must be made. All areas without emulsion need to be washed with water.4) The stencil is placed on the table for printing, and the garment or fabric is placed under the stencil. Using a manual or automatic press, the ink is transferred to the fabric. The final product must then be dried.

In silk printing, separate screens are used for each color. For example, if the design has four colors, four separate screens are used, and each screen transfers one color to the fabric.Silk screen printing is a method where a designed image is printed on a flat surface using silk screens, ink, and specific squeegees.The steps for silk screen printing are as follows:1) The desired design is printed on calico paper in black and white.2) Depending on the desired surface and fabric type, a suitable screen is chosen. This screen is coated with a light-sensitive substance and dried in a light-free environment. When exposed to light, it hardens, creating a stencil.3) A special sheet containing the design is attached to the stencil. The entire setup is exposed to strong light, making the exposed parts of the stencil hard and firm, while the remaining screen areas covered by the design remain soft.For each color, a separate stencil must be made. All areas without emulsion need to be washed with water.4) The stencil is placed on the table for printing, and the garment or fabric is placed under the stencil. Using a manual or automatic press, the ink is transferred to the fabric. The final product must then be dried.

5) Label Printing on Fabric

In this method, printing is done on PVC. The printed areas are cut, and the cut design or logo is transferred to the fabric using a heat press. In single-color jobs, there is no need for printing. The logo or desired design is cut from colored material and transferred.The final product is waterproof and washable and is suitable for low quantities. In the past, other methods such as rotary printing, roller printing, and mold printing were used, but they are not practical today.

6) Flock Printing

Flock printing is essentially a style in silk printing where a layer of velvet is added to the work. Flock printing is done using a specific adhesive and fine powders. In this method, first, the adhesive is placed on the fabric using a stencil, and then velvet powder is applied to the adhesive.Flock printing has high quality and can be executed on various fabrics. However, it is expensive, and there are limitations in transferring details. Restrictions on available colors are another drawback of this type of printing.

7) Embroidery of Logo or Design

In addition to printing on fabric, logos or special designs can be embroidered on the fabric. Embroidery can be done in up to eight colors and is carried out in several ways:a) Direct embroidery is done directly on the fabric.b) First, monochrome embroidery is done on the fabric, and then it is embroidered on the garment or patch. Usually, the cost of embroidery is estimated based on the unit of 12,000 stitches. The maximum space that the machine can embroider on is 20 to 25 centimeters, usually used for bed sheet work or promotional t-shirts. However, for large sizes, it is better to use printing instead of embroidery. One of the advantages of embroidery is that the number of colors used does not affect the cost, and the price is estimated based on the density level.

Reviews

There are no reviews yet.